|

Ni |

Cr |

Fe |

C |

Mn |

S |

Si |

Cu |

|

≥72.00 |

14.00-17.00 |

6.00-10.00 |

≤0.15 |

≤1.00 |

≤0.015 |

≤0.50 |

≤0.50 |

|

Ni |

Cr |

Fe |

C |

Mn |

S |

Si |

Cu |

|

≥72.00 |

14.00-17.00 |

6.00-10.00 |

≤0.15 |

≤1.00 |

≤0.015 |

≤0.50 |

≤0.50 |

Tensile Strength

≥550Mpa

Yield Strength

≥205Mpa

Elongation

≥35%

|

Pipe - Seamless |

ASTM B167, ASME SB167 |

|

Pipe - Welded |

ASTM B517, ASME SB517 |

|

Tube - Seamless |

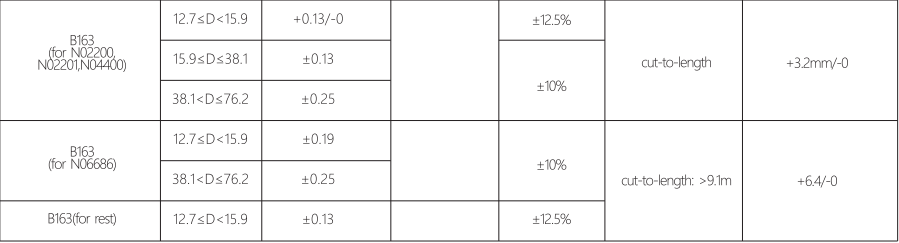

AMS 5580, ASTM B163, ASTM B167, ASME SB163, ASME SB167 |

|

Tube - Welded |

ASTM B516, ASTM B751, ASME SB516, ASME SB751 |

Marked Pipe Sample: XTD ASTM B167 UNS N06600 SEAMLESS 42.2x 3.56*6000MM HEAT NO. 2023121205A15

Nickel Alloy 600, also sold under the brand name Inconel® 600. It is a unique nickel-chromium alloy that is known for its oxidation resistance at higher temperatures. It is highly versatile and can be used in everything from cryogenics to applications that present elevated temperatures up to 2000°F (1093°C). Its high nickel content, a minimum of Ni 72%, combined with its chromium content, provides users of Nickel Alloy 600 a number of benefits including:

Its chromium content gives the alloy resistance to sulfur compounds and various oxidizing environments. The chromium content of the alloy makes it superior to commercially pure nickel under oxidizing conditions. In strong oxidizing solutions, like hot concentrated nitric acid, 600 has poor resistance. Alloy 600 is relatively unattacked by the majority of neutral and alkaline salt solutions and is used in some caustic environments. The alloy resists steam and mixtures of steam, air, and carbon dioxide.

Alloy 600 is non-magnetic, has excellent mechanical properties and a combination of high strength and good workability and is readily weldable. Alloy 600 exhibits cold forming characteristics normally associated with chromium-nickel stainless steels.

Typical corrosion applications include titanium dioxide production (chloride route), perchlorethylene syntheses, vinyl chloride monomer (VCM), and magnesium chloride. Alloy 600 is used in chemical and food processing, heat treating, phenol condensers, soap manufacture, vegetable and fatty acid vessels and many more. Link to alloy 601 that was developed to be more resistant to high-temperature oxidation than alloy 600.

If you have any enquiry about quotation or cooperation,please feel free to email us at admin@xtd-ss.com or use the following enquiry form. Our sales will contact you within 24 hours. Thank you for your interest in our products.